In early aquaculture, moist natural products such as low-value fish or scraps from slaughterhouses and fisheries were used as food sources. The preparation of this type of feed did not require very advanced technology aside from mincers, mixers, etc.

Today, aquaculture accounts for 50% of global fish consumption, and the forecasts project an increase in the coming years. This rapid growth has also caused a rapid evolution in the technology used to manufacture aquaculture feed.

Specific aquaculture feeds have unique characteristics that differentiate them from other types of animal feed. They have very high protein and fat content, and at the same time, they require certain characteristics, such as floatability and stability in water.

Today, dry feed is widely used because it is easy to acquire, transport, store and distribute, and due to the good results obtained in terms of growth and conversion ratio.

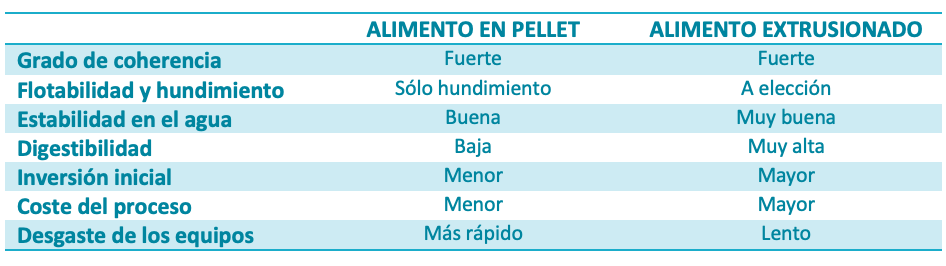

Today, the two most widely used technologies for the manufacture of aquaculture feed are pelletisation and extrusion. Feed produced with these processes is denser, has lower moisture content and allows better preservation. One of the main differences between pelleted and extruded feed is that, whereas pellets sink, the buoyancy of the extruded feed can be controlled during the manufacturing process. However, extrusion has other advantages that we will now examine.

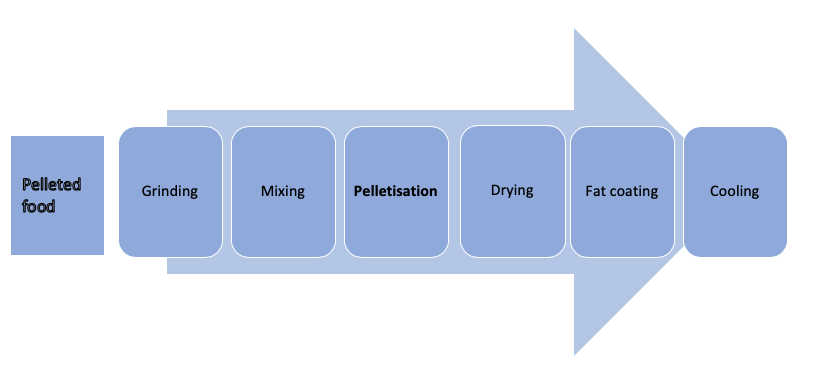

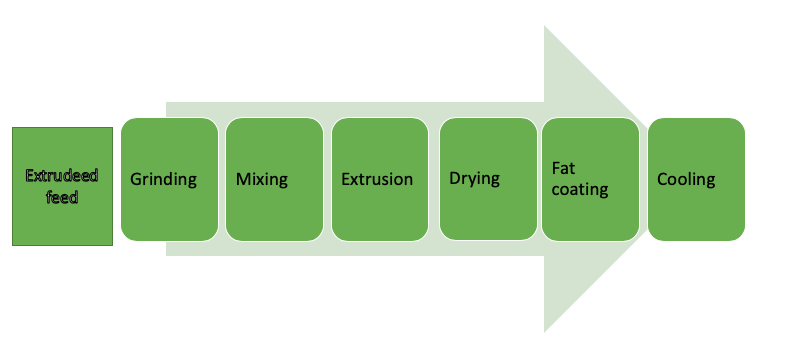

Both manufacturing processes have common phases, but the pelletisation or extrusion phase is the one that makes the difference in the final product.

Pelletisation consists of compressing small particles to create larger ones called pellets, and during this process, moisture, temperature and pressure come into play. One of the main advantages of pelleted feed is the lower manufacturing cost compared to extrusion technology; however, it has many drawbacks that are solved with extrusion technology. One of the biggest disadvantages of pelletisation is the rapid sinking speed (an estimated 10 to 15% of pelleted feed is lost due to sinking), which means higher feed costs, a less profitable product, and a greater environmental impact due to pollution. Also, the nutrients in pellets dissolve more rapidly in water, making it lower-quality fish feed than extruded feed.

The extrusion process is widespread today, as it can be used to manufacture all kinds of feeds, whether buoyant, fast or slow sinking, depending on the needs of each species.

Extrusion is a process involving high temperatures and short times, which minimises nutrient loss while improving the digestibility of starches and proteins compared to pelleted food. Extrusion is a process in which the food is not only compressed, as in pelletisation, but also ‘cooked’, which is why it requires higher levels of moisture, temperature and pressure than pelletisation. All these requirements must be met to achieve the desired degree of expansion when it leaves the extruder. In addition, as mentioned above, its other advantages include lower pollution, longer stability in water (from 12 to 36 hours) while maintaining all its nutrients, greater digestibility, high efficiency and a high conversion rate. As a result, extruded feed is a higher quality product that increases the profitability of fish farms.