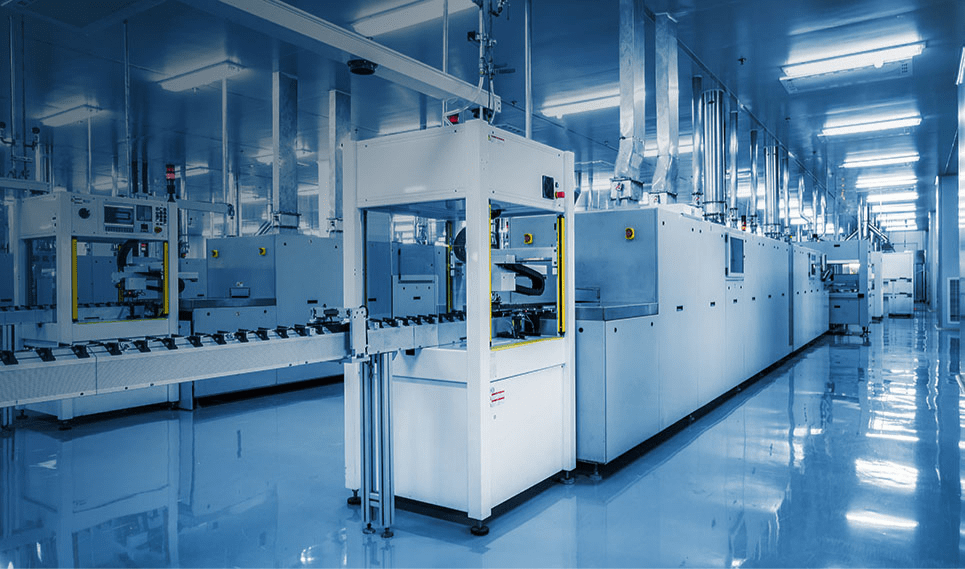

In the world of animal nutrition, the technology used in food manufacturing is of fundamental importance. This is reflected mainly in the type of machinery used during the grinding, processing or drying processes, some of the essential phases included in the production of food for pets and aquaculture fish.

The technical specifications of this type of industrial machinery will have a direct impact on the final quality of the food items produced. Investment in R&D&I is vital for ensuring a final result that ensures the improved processing of raw materials, reduced costs, guaranteed sustainability and better animal health. In this sense, the best option is engineering that offers a production process with the following characteristics:

– Efficiency.

– Speed.

– Easy maintenance and cleaning.

– Quality control.

– Great final food taste and digestibility.

But what optimal functions should the machinery used at each stage of the production and transformation process of food for pets and aquaculture fish? Let’s look at a few examples.

Ingredient grinding

Grinders are one of the main elements used in the production of animal food. Its main technical features should include the following:

– Guaranteed capacity for grinding both fresh and frozen meat, as well as other ingredients, including fine and thick products, without the need to change any of the mechanical parts.

– Possibility of full assembly and disassembly.

– The use of stainless steel parts.

In this sense, choosing the right brand and technology will have a positive direct impact on the final product. Below are a number of the principal benefits:

– The possibility of obtaining final products with differentiated textures tailored to meet varying needs: mousse, pâté, pieces, etc.

– Enhanced product tasted, adapted to each breed and species.

– Optimum grain definition following grinding. – Controlled temperature that maintains grinding quality, preventing squashing and excessive softness.

– Grinding fresh meat immediately prior to mixing with the dry ingredients, thereby guaranteeing freshness and correct processing.

Food processing

At Derwent Group, we are pioneers in extrusion technology, one of the most commonly used processes in food production. This process guarantees greater food density, lower levels of moisture and enhanced preservation. Extrusion can be used to produce all types of food: floating, fast or slow sinking feed, in accordance with the needs of each species. In order to guarantee the most appropriate production processes, the machinery used should feature the following:

– Insulated cold storage chambers to preserve the cold chain and product quality.

– Dual axis mixing / kneading machine.

– Extra fine grinding of the raw material (0.2 mm).

– Electronically controlled dispenser.

– Option of preparing and mixing meat of different species.

These characteristics will allow for the production of food products with the following benefits:

– Dry foods with a high fresh meat content.

– Outstanding taste and digestibility.

– Homogenous mix of fresh meat and dehydrated ingredients.

– Improved absorption of the oil and covering sauce, making the food tastier.

– Food with a lower adjusted level of inorganic content.

Drying line

During the food drying process, in addition to the main drying machine, it is advisable to have a transport system that allows for the delicate handling of the product to prevent any breakages. Stainless steel machinery is the best option to prevent corrosion and allow for easy cleaning. For the drying process, gravity-based vertical flow technology is one of the most innovative options available on the market.

This type of drying facilities offers the following benefits, guaranteeing an optimal procedure:

– Energy efficiency: savings on gas and electricity in comparison with conventional systems.

– Versatile product drying: a range of 1 mm to > 20 mm.

– Uniform moisture levels of the final product.

– Automatic and independent monitoring of the air volume and temperature, as well as drying times for each zone.

– Automatic and ongoing measuring of drying air humidity and product moisture levels.

– Prevention of food cross-contamination.

– Reduction of inspection and cleaning times.

– Fewer mechanical parts movements, cutting maintenance and repair times.

– Lower temperature of the air released into the atmosphere.

These are just three clear examples of how effective investment in machine innovation and technology used in animal food products can have a highly positive impact on both product development and the end result.